A unique technology for aseptic filling

Our aseptic filling machines are engineered to take the risk and complexity out of your operations. Designed for smooth, extended production runs between Clean-in-place (CIP) processes, they ensure top-tier food safety.

Ecolean packages arrive pre-formed, pre-sterilised, and hermetically sealed to customer site. This eliminates the risks associated with on-site sterilisation and the use of hazardous chemicals.

Ecolean's aseptic filling – simplicity and safety

Learn how the unique benefits brings efficiency to your operations.

Ecoleans filling machines for aseptic solutions

Explore the benefits

Aseptic system

Ecolean delivers pre-formed, pre-sterilised and hermetically-sealed packages that are ready to fill. There is no need for package forming or package sterilisation on the customer's site. This offers customers a simple and cost-efficient operation with low risk and the highest standard of food safety.

Learn more about our Aseptic packaging.

High efficiency

Ecolean aseptic filling machines enable long production runs between CIP processes, that outperform most conventional packaging systems:

-

High acid products (PH <4.6) 96-hour production runs (such as for juice)

-

Low acid products (PH>4.6) 55-hour production runs (such as for milk or yoghurt)

No water consumption

Ecolean filling systems use no water during filling or ice water for cooling, which enables customers to use less fresh water in their operations. Water is only used during CIP and chamber cleaning.

Low labour intensity

-

No package forming or sterilisation is performed at the customer site.

-

Simple quality controls save time for the operator.

-

Less than 25 minutes/hour is needed to operate an Ecolean filling machine – including the Ecolean recommended quality controls.

Less chemicals

Ecolean's pre-formed and pre-sterilised packages ensure negligible hydrogen peroxide consumption during production.

This not only significantly reduces chemical costs during production, but also enhances safety for the machine operator as concentrated hydrogen peroxide is not handled during production. Only a 1% hydrogen peroxide spray is used inside the chamber, which minimises exposure to hazardous chemicals.

Less liquid food waste during production

The design of the Ecolean filling system and the limited number of quality controls needed, minimise the wastage of your liquid food product during the filling process. This helps to lower operating costs and food waste.

Low energy usage

Ecolean filling machines are designed with low-energy consumption in mind. During production, the Ecolean filling machine EL6 only uses 8.5 kW per hour.

Flexible system for switching between packaging formats

Ecolean filling machines offer operational flexibility and low downtime when switching packaging sizes. Switching to another packaging size only takes on average 15-20 minutes, depending on operator experience.

Ecolean filling machines also offer flexibility in terms of being able to fill several different packaging sizes. Ecolean® Air Aseptic 125 ml, 200 ml, 250 ml can be filled with the EL6 and EL4+ filling machines, and Ecolean® Air Aseptic 500 ml, 750 ml and 1,000 ml with the EL3+ filling machine.

Ready-to-fill packages

The pre-formed, pre-sterilised and ready-to-fill packages are supplied hermetically sealed by Ecolean plants. Before opening, filling and sealing in the filling machine, the outer surfaces of the packages are re-sterilised.

Optimise your operations

To reduce labour needs and downtime, Ecolean filling machines feature automatic roll-changes, material splicing, and an advanced monitoring system and operator interface. The CIP process is also fully automated along with external cleaning that occurs automatically in an integrated circulating cleaning system.

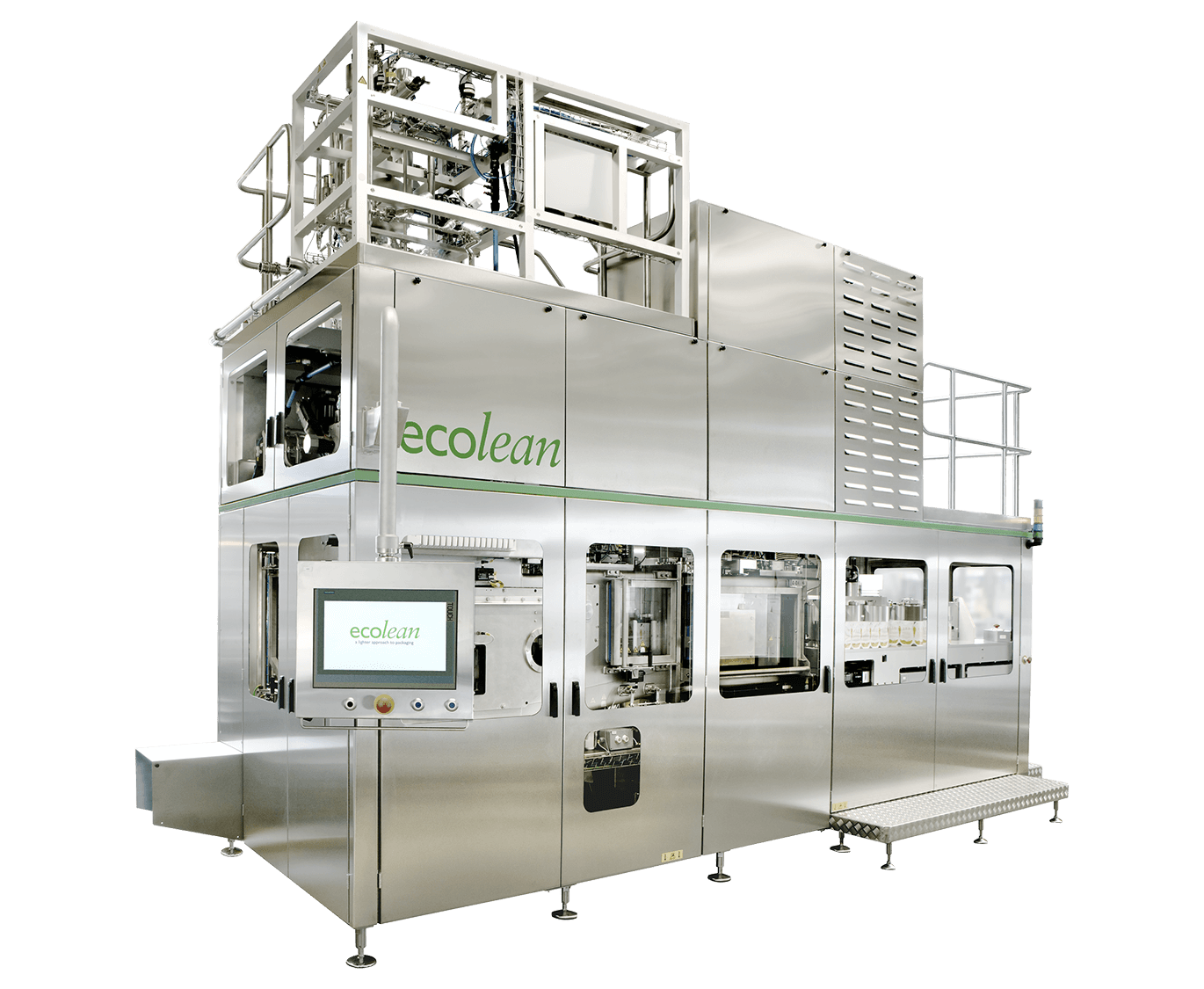

Discover our filling machines for aseptic solutions

EL6 - Ambient Portion-size

The Ecolean EL6 aseptic filling machine is designed for liquid food and beverage products for ambient distribution and has the highest capacity of Ecolean’s filling machines. The EL6 opens, fills and seals Ecolean’s ready-to-fill, pre-sterilised and hermetically sealed packages. The filling machine features a filling zone with six fillers with a capacity of up to 18,000 Ecolean® Air Aseptic packages per hour.

The design is compact and easy to operate and can switch between different package sizes. To reduce labour needs and downtime, the Ecolean EL6 features automatic roll-changes, material splicing, and an advanced monitoring system and operator interface. A fully automated cleaning and sterilisation system ensures food safety and quality.

-

Package sizes: 125 ml, 200 ml and 250 ml

-

Capacity: Up to 18,000 packages/hour

-

Footprint: L: 7.5m, W: 2m, H: 4.3m

-

Nitrogen kit optional

EL4+ – Ambient portion-size

The Ecolean EL4+ aseptic filling machine is designed for liquid food and beverage products for ambient distribution. The EL4+ opens, fills and seals Ecolean’s ready-to-fill, pre-sterilised and hermetically sealed packages. The filling machine features a filling zone with four fillers with a capacity of up to 12,000 Ecolean® Air Aseptic packages per hour.

The design is compact and easy to operate and can switch between different package sizes. To reduce labour needs and downtime, the Ecolean EL4+ features automatic roll-changes, material splicing, and an advanced monitoring system and operator interface. A fully automated cleaning and sterilisation system ensures food safety and quality.

-

Package sizes: 125 ml, 200 ml and 250 ml

-

Capacity: Up to 12,000 packages/hour

-

Footprint: L: 7.3m, W: 2.6m, H: 4.3m

-

Nitrogen kit optional

EL3+ – Ambient family-size

The Ecolean EL3+ aseptic filling machine is designed for liquid food and beverage products for ambient distribution. The EL3+ opens, fills and seals Ecolean’s ready-to-fill, pre-sterilised and hermetically sealed packages. The filling machine features a filling zone with three fillers with a capacity of up to 7,500 Ecolean® Air Aseptic packages per hour.

The design is compact and easy to operate and can switch between different package sizes. To reduce labour needs and downtime, the filling machine includes a package reel unwinder with an automatic ultrasonic splice and reel changes without machine stoppages. The servo-driven fill-and-seal technology maintains simple operations yet with a high production level. A fully automated cleaning and sterilisation system ensures food safety and quality.

-

Package sizes: 500 ml, 750 ml and 1,000 ml

-

Capacity: Up to 7,500 packages/hour

-

Footprint: L: 7.8m, W: 2.5m, H: 4.1m

-

Ecolean® integrated packer optional

Explore our packages for ambient products

Discover our range of packages and sizes for the ambient distribution of milk, cream, yoghurt, still drinks, cafe latte and tea drinks.