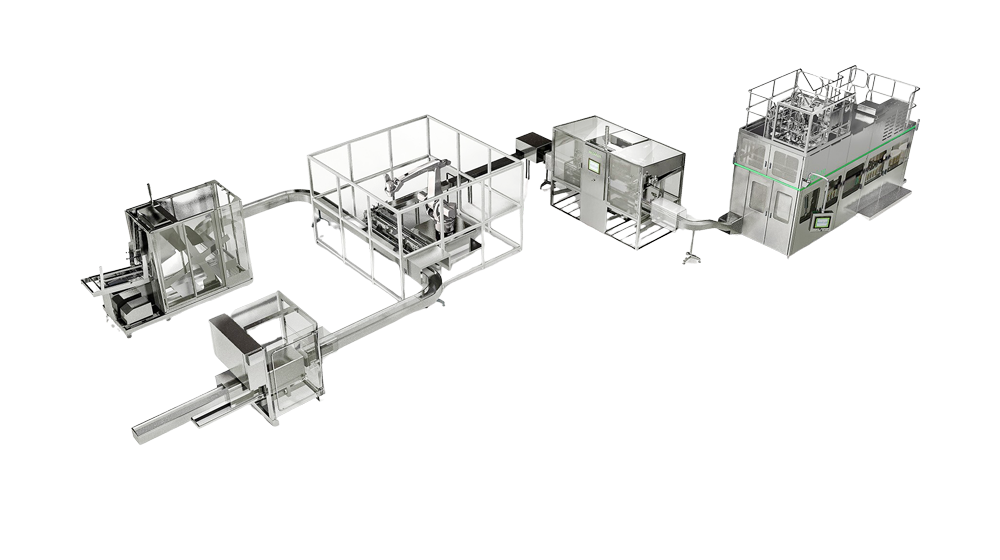

Tailored solutions from start to finish

With over 25 years of experience filling Ecolean lightweight packages, we offer comprehensive line solutions tailored to your unique needs.

From filling machines to straw applicators, packers, conveyors, palletisers, and stretch wrapping, we are dedicated to providing full solutions. By collaborating with trusted third-party manufacturers, we ensure flexible, cost-effective filling lines that meet your exact requirements.

The best possible line solution

We aim to provide the best possible line solution for each customer to meet their specific requirements, and can assist in line design, line configuration and line performance. We recommend proven packer systems, marking and labelling equipment, weighing format checks, conveyor solutions, palletisers, stretch wrapping and pallet labelling among other equipment solutions. Contact us for more information and support.

The importance of secondary packaging

Well-designed secondary packaging plays a crucial role in protecting your products throughout their distribution. It also improves shipping and storage efficiency, while enhancing branding and marketing. Ecolean can provide customised secondary packaging solutions, such as cardboard boxes and plastic crates, upon request. We test and verify all our solutions to ensure they work perfectly with both Ecolean packages and our filling lines. We offer various options including multipack and shelf ready display solutions.

Filling line solutions

Ecolean line equipment

Integrated package date printer at your site

Our printing solutions can print on the top or underside of the Ecolean package. Printing on the top side occurs at the unwinding unit. Printing on the underside is preferred after filling, close to the outfeed conveyor.

Package conditioning Unit (EPC4)

The unit ensures that the external surface of the package is clean and dry, prior to secondary packaging, and includes automatic conveyor cleaning.

- Features a compact design and enclosed cleaning area.

- Exterior dimensions: H 1.7m, W 1.0m, L 0.7m

CIP unit (ECIP1)

The automatic Clean-in-place (CIP) unit is specially designed for Ecolean filling machines.

- Maintains cleaning time, detergent temperature, flow and concentration.

- User-friendly and cost-effective.

- Exterior dimensions: H 1.8m, W 0.8m, L 1.2m

Package Testing Unit (EPTU3)

The unit provides a quick and easy quality control of package integrity.

- Precise force application ensures accurate testing.

- Exterior dimensions: H 0.8m, W 0.5m, L 0.8m

Straw Applicator (ES4)

The applicator provides filled portion-sized packages with straws, using hot-melt glue. Dual applicator heads reduce the risk of line stoppage and enable the maintenance of one applicator head at a time during full production.

- Capacity: 18,000 packages per hour.

- Exterior dimensions: H 2.5m, W 3.7m, L 1.4m.

Mini Accumulator (EMA4)

- Placed between the filling machine and downstream equipment to eliminate unnecessary waste caused by a quick stop.

- Exterior dimensions: H 1.2m, L 1.2m, W 2.4m.

Packer unit

Packer units are available for packing Ecolean packages into secondary boxes. A flexible picker system with Delta robots that either vacuum grip packages one by one or multi picks. The units ensure full flexibility in the orientation and configuration, including horizontal loading into boxes.

Case erector unit

The unit folds and seals the underside of cases. Available in right or left handed versions. Case outfeed is available with the short side of case leading.

Case closer unit

The unit folds and seals the top of cases. Available is right or left handed versions. Case outfeed is available with the short side of case leading.

Secondary packaging label printer

Printers for printing labels on secondary packaging, such as on cardboard boxes. For the application of one label on one side of the box.

Palletiser system

The compact, space-saving and modular system can be adapted to most premises. This palletiser is user-friendly and reliable to minimise the need for maintenance and repairs.

As the system does not lift the products, it allows for large differences in the dimensions and shape of the products. The palletiser can therefore palletise radically different types of packaging without change-over processes or tool changes – and product changes can be made to an existing unit without manual change-overs.

Stretch film unit

The stretch film unit with a ring design and unlimited wrap patterns is used to protect and secure pallets. The unit is ideal for a range of applications, including unstable and lightweight products due to no centrifugal forces, which simplifies the wrapping of challenging loads.

The unit has an integrated top sheet dispenser and protects the load against dust or water. It also provides significant space savings on the factory floor.

Pallet label printer

The printer is suitable for printing A5 format labels for pallets. It applies one label on two sides of the pallet.

Simplicity guaranteed

With an Ecolean line solution, you avoid the complexity of several different suppliers on your filling line. Ecolean takes responsibility for the entire solution, and all line equipment is already verified and fitted for your particular needs.

Discover our range of lightweight packages

Our innovative packages are crafted for convenience, effortlessly serving both chilled and ambient liquid foods.