Efficiency that fits anywhere

Our filling machines for chilled products are built for flexibility and efficiency. Their compact design saves valuable shop floor space. Simplicity drives every step – from installation and setup to daily operation and maintenance. Ecolean's efficient filling machines help reduce cost at every level, from low energy and water usage to minimising downtime during format changes.

Ecolean's filling machines for chilled solutions

Explore the benefits

High efficiency

Ecolean filling machines enable long production runs that outperform most conventional packaging systems.

No water consumption

Ecolean filling systems use no water during filling or ice water for cooling, which enables customers to use less fresh water in their operations. Water is only used during CIP and chamber cleaning.

Low labour intensity

-

No package forming at customer site.

-

Easily managed quality controls save time for the operator.

Less liquid food waste during production

The design of the Ecolean filling system and the limited number of quality controls needed minimise the wastage of your liquid food product during the filling process. This ensures lower operating costs and food waste.

Low energy use

Ecolean filling machines are designed with low energy consumption in mind. During production, the Ecolean filling machines EL1+ and EL2+ only use 1.7 kW per hour.

Flexible system for switching between packaging formats

Ecolean filling machines offer operational flexibility and low downtime when switching packaging sizes.

Switching to another packaging size only takes on average 10 minutes, depending on operator experience.

Ecolean filling machines also offer flexibility in terms of being able to fill several different packaging sizes with the same machine.

Compact design

The compact design of Ecolean filling machines ensures they take up less shop floor space. They also allow easy access to all machine functions and service points.

Discover our filling machines for chilled solutions

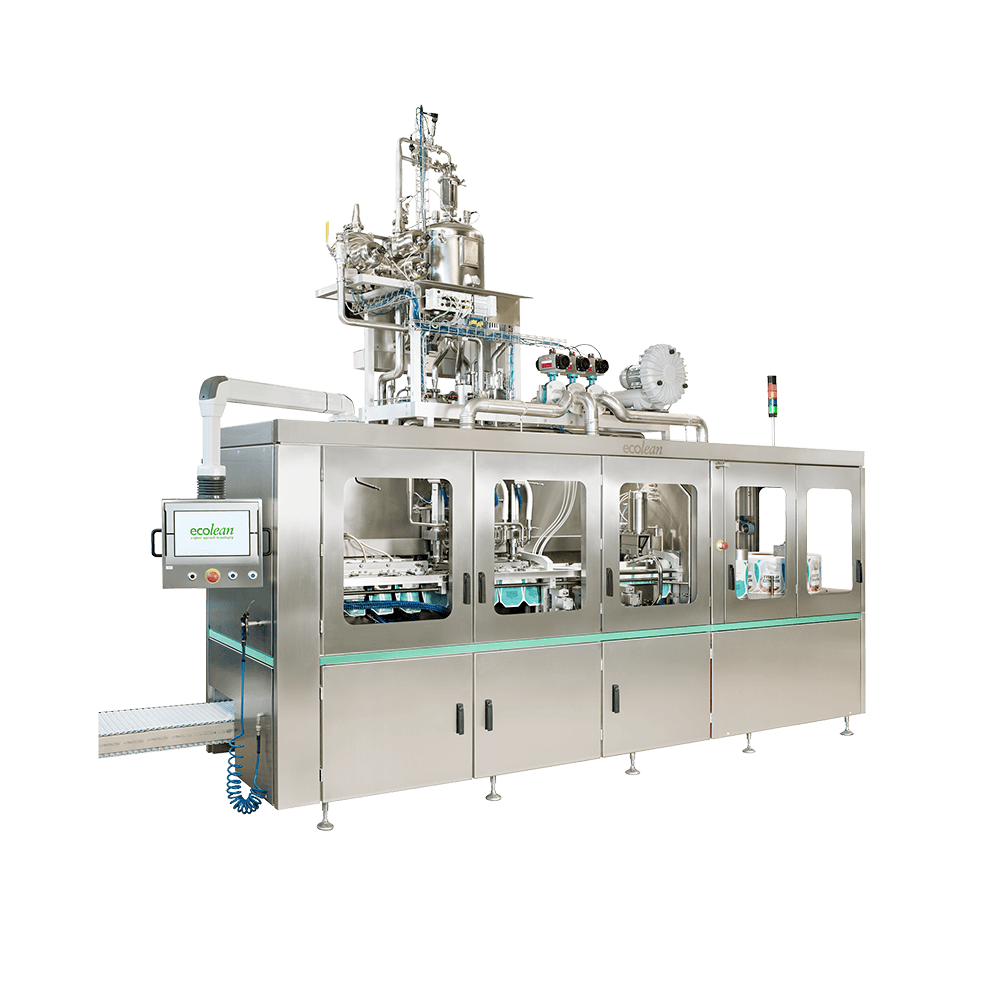

EL2+ – Chilled Portion-size

The Ecolean EL2+ filling machine is designed for liquid food and beverage products for chilled distribution. The EL2+ opens, fills and seals Ecolean’s ready-to-fill, hermetically sealed packages. The filling machine features a filling zone with five fillers with a capacity of up to 12,000 Ecolean® Air packages per hour.

The design is compact and easy to operate and can switch between the different package sizes. A fully automated cleaning system for the filling zone ensures food safety and quality. A steam system can be added to enable the sterilisation of the entire filling system.

-

Package sizes: 125 ml, 200 ml, 250 ml

-

Capacity: Up to 12,000 packages/hour

-

Footprint: L: 5m, W: 1.7m, H: 3.7m

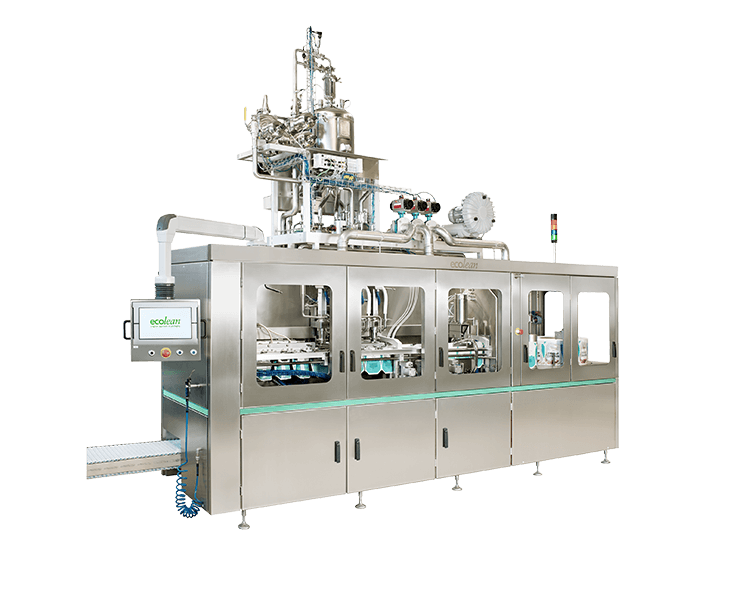

EL1+ – Chilled Family-size

The Ecolean EL1+ filling machine is designed for liquid food and beverage products for chilled distribution. The EL1+ opens, fills and seals Ecolean’s ready-to-fill, hermetically sealed packages. The filling machine features a filling zone with four fillers with a capacity of up to 7,000 Ecolean® Air packages per hour.

The design is compact and easy to operate and can switch between the different package sizes. A fully automated cleaning system for the filling zone ensures food safety and quality.

-

Package sizes: 500 ml and 1000 ml

-

Capacity: Up to 7,000 packages/hour

-

Footprint: L: 5m, W: 1.7m, H: 3.7m

-

SnapQuick™ reclosing device optional

SnapQuick™

The innovative reclosing feature SnapQuick™ takes reclosure to the next level by being convenient and easy to use. Unlike many other reclosing alternatives, SnapQuick™ is lightweight and part of the package.

The SnapQuick™ reclosing feature is integrated into the package, without compromising functionality. Once the package is opened, it can be easily closed by simply folding and giving the top of the package a light pinch. SnapQuick™ is made from PET and adds less than 0.38 grams to the total package weight, which is substantially less than conventional reclosing devices such as screw caps. Just fold and snap!

SnapQuick™ is available for family-sized Ecolean® Air packages. The SnapQuick™ applicator modules, available for EL1+ filling machines, connect to the filling machine as an integrated part and are applied to the package prior to filling.

Explore our packages for chilled products

Discover our packages for cold chain distribution. Milk, yoghurt, cream, sour cream, soy drink and different still drinks have all seen the inside of an Ecolean® Air package.